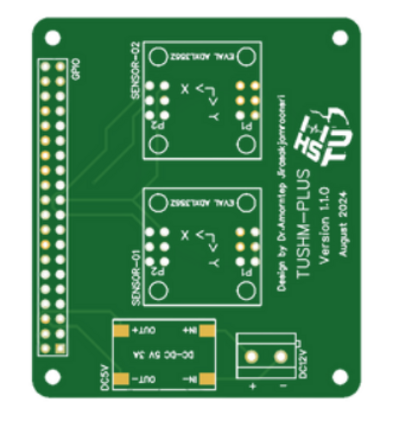

Capable of monitoring vibrations caused by natural hazards such as earthquakes, storms, or landslides across all types of structures — including buildings, bridges, towers, and infrastructure — to assess their stability in real-time.

Accurately tracks vibrations from industrial machines to identify abnormal behavior, prevent mechanical failure, and support predictive maintenance strategies in manufacturing or production facilities.

Monitors vibration patterns generated by different types of vehicles — such as trucks, trains, or heavy equipment — to evaluate roadway impact, mechanical condition, or transport safety.

Measures vibrations resulting from construction activities like drilling, piling, and demolition to assess impact on surrounding structures and ensure compliance with safety regulations.